- 23 Jan 2021

- Dan

- Reviews

- Comments: 0

Choosing the right air compressor for your business requires careful consideration of several factors. Here are some key points to keep in mind:

- Size Matters

Selecting the right size of air compressor is crucial to avoid wasting time and resources. An undersized compressor may not provide sufficient pressure, while an oversized one can lead to unnecessary energy consumption. Assess your needs and choose a compressor that matches your requirements.

- Airflow and CFM

The airflow of an air compressor, measured in cubic feet per minute (CFM), determines its performance. Ensure that the CFM output of the compressor is greater than the operational CFM requirement of your tools and equipment. Consider the type of tools you will be using and their specific CFM requirements to make an informed decision.

- Consider Your Work Environment

The work environment plays a crucial role in determining the type of drive system your air compressor specialists should have. Electric motors are less expensive and require less maintenance, while gasoline engines offer increased portability. Assess your work environment and choose the drive system that suits your needs best.

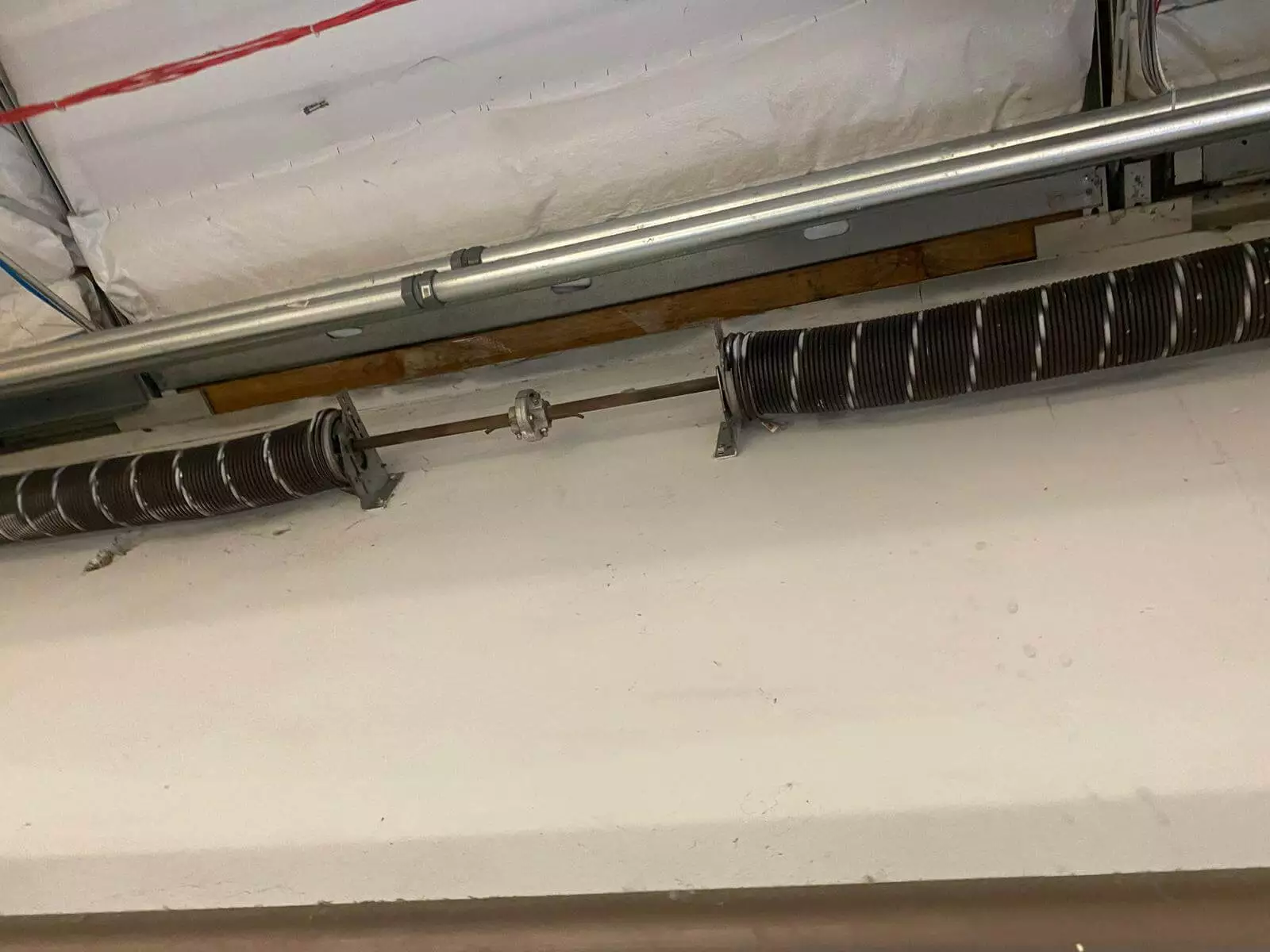

- Tank Size

The size of the compressor tank depends on the nature of your usage. If you require quick bursts of compressed air, a small tank may suffice. However, sustained periods of use will require a larger tank to ensure a continuous supply of compressed air.

- Tools and PSI Requirements

Consider the specific tools you will need for your business and determine the required pressure (measured in pounds per square inch or PSI) the compressor should be able to provide. Ensure that the compressor can deliver the necessary PSI to operate your tools effectively.

- Horsepower Requirements

Evaluate the horsepower needed for your air compressor to produce enough air for your applications. Balancing horsepower and CFM is crucial, as a high horsepower but low CFM compressor may lead to overheating and a shorter service life.

- Control Systems

Consider the control systems that best suit your requirements. Start/stop systems are useful for tasks that don’t require continuous air, while constant speed control is ideal for applications with frequent starts. Dual control systems offer the flexibility to choose between start/stop and constant speed modes.

- Protection and Additional Features

If you plan to use the air compressor outdoors, ensure that it has adequate protection against water and extreme temperatures. Look for features like stainless steel finger valves to prevent corrosion, oil-monitoring devices to maintain proper lubrication, and one-piece connecting rods for reduced maintenance costs.

- Future Planning

When purchasing an air compressor, consider your future needs and growth projections. If you anticipate expanding your operations or adding more technicians, a larger compressor may be necessary to accommodate increased demand.

- Price and Company Reputation

While price is an important consideration, it should not be the sole determining factor. Consider the overall cost and expected service life of the compressor. Look for a reputable company with a long-standing presence in the industry, a wide range of compressor options, and a strong service and distribution network.

By carefully considering these factors, you can choose an air compressor that meets your specific business needs and provides optimal performance.

Hi, I’m Dan and I write blogs for businesses. I’ve been doing this since 1994 and have written over 10,000 blog posts (and counting). I love writing about what you’re passionate about and how to make your business successful. So if you want to know more about blogging or social media marketing, just let me know!